2023.10.10

[Case Study] 2022 (Gyoke) No. 10019, Request for Rescission of Trial Decision (Case of Dies for Wires with Polygonal Cross-Sections) [Translated from original Japanese]

Published on June 2, 2023

Patent Attorney, Chiaki Tateyama

1. Case History

| Date | Procedure | Remarks |

|---|---|---|

| September 6, 2015 | Application filed | |

| November 4, 2016 | Patent granted |

Claims 1-16 |

| May 12, 2017 | Objection |

Issues: Novelty, Inventive step |

| January 30, 2019 | Objection decision |

Claims 1-12 maintained |

| April 21, 2020 |

Request for invalidation trial |

Issues: Introduction of new matter, Support requirements, Clarity, Novelty, Inventive step |

| January 20, 2022 | Trial decision |

The request dismissed |

| February 28, 2022 | Request for rescission of trial decision | |

| November 16, 2022 | Judgement |

The trial decision rescinded |

2. Patented Invention

[Claim 1]

- A drawing machine comprising: a die holder (902) holding a drawing die (101) having a generally cylindrical shape and rotating the drawing die about a central axis of the generally cylindrical shape of the drawing die; and

- a box (905) into which a material wire (A-1) is drawn into the drawing die after a lubricant stored therein is applied to the material wire;

- wherein an opening of a bearing portion (101b) of the drawing die has a generally polygonal cross-sectional shape, and

- wherein the cross-sectional shape of the opening is the same along a drawing direction of the material wire.

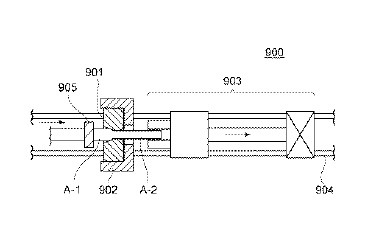

Fig. 1

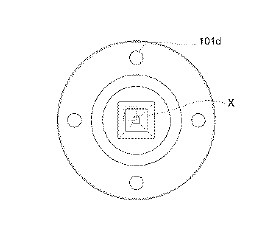

Fig. 7

[Technical Field]

[0001]

This invention relates to dies, especially those used in a drawing process.

For the production of wires for construction where they are required to be straight, it is common to use drawing machines to perform the drawing process.

[Background Art]

[0015]

When steel materials such as bars and wires are drawn by a die, a powdered solid lubricant is generally contained in a box 905 provided in front of the die, and this lubricant adheres to the wire A. This powdered lubricant becomes an oil film due to the heat generated in an approach portion 901a during drawing in a drawing machine 903. The adhesion of the powdered lubricant to this oil film forms a clump. This clump grows larger with each successive drawing process, and the supply of lubricant to the surface of the material wire A-1 is inhibited. As a result, scratches occur on the surface of the finished wire A-2.

[0016]

In addition, it is necessary to stop work when removing these clumps, resulting in an inevitable decrease in production volume. This problem is particularly serious when manufacturing twisted bars, and is one of the reasons why the production cost cannot be lowered.

[Technical Problem]

[0020]

The purpose of this invention is to provide a means of preventing the formation of lubricant clumps as much as possible and reducing the time required for the maintenance as much as possible, resulting in a reduction in the cost of manufacturing wires with polygonal cross-sections.

[Description of Embodiments]

[0054]

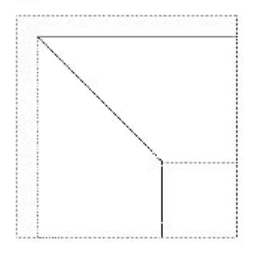

In the conventional drawing die 901, two sides of the cross-section of the bearing portion 901b were butted together without machining for the purpose of making the corner of the bar right-angled. Therefore, when the cross-sectional shape of the bearing portion 901b is a square as shown in Figs. 3 and 6, each side intersects at a right angle.

Here, the cross-sectional shape of the opening of the bearing portion 901b of the die 901 shown in Fig. 6 is a square, which is a kind of polygon. This is referred to as the “basic polygonal cross-section.”

[0055]

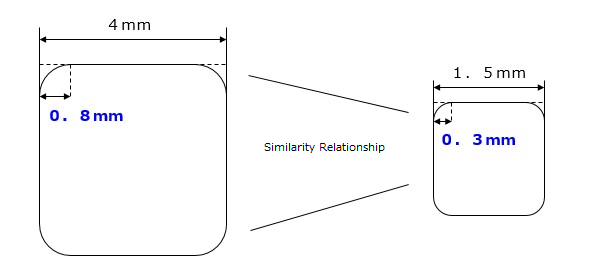

On the other hand, Figs. 7 and 10 show the bearing portion 101b of the drawing die 101 of the present invention. The cross-sectional shape of the bearing portion 101b is characterized in that the “corner” of the “basic polygonal cross-section” shown in Fig. 6 is replaced with a circular arc, or curve, to connect the two sides. Specifically, when manufacturing a bar with a square cross-section of 4 mm per side, one “corner” of the opening of the bearing portion 101b of the drawing die 101 is connected by a circular arc (curve) with a curvature of about 0.8 mm in radius.

This makes it difficult for the clumps of lubricant that have accumulated at the “corner” to solidify in one place.

Fig. 6 (Conventional Art)

Fig. 10 (Patented Invention)

[0057] In this document, a shape in which at least one corner of a “square” is rounded, i.e., one or all “corners” are rounded, is called a “generally square shape.” Similarly, a polygon including a square with one or all corners rounded is called a “generally polygonal shape.”

[0059] This eliminates the “corners” where lubricant accumulates. As a result, the lubricant in this die 101 behaves in the same way as a die with a circular cross-section, and clumps of lubricant are less likely to form.

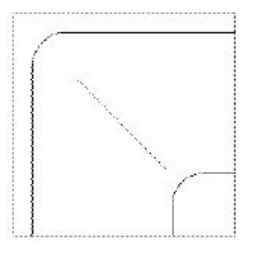

[0076] Although arcs were used to eliminate “angles” above, they can be configured as a set of obtuse angles. Fig. 13 shows this set of obtuse angles. In other words, it is included in the scope of the present invention to make a “corner” composed of a single 90-degree angle to be composed of nine obtuse angles, so that clumps do not accumulate in one place. There is no problem even if the “corners” are replaced by free curves, not limited to arcs.

Fig. 13

3. Plaintiff’s Claim

(1) Distinction between “basic polygonal cross-section” and “generally polygonal shape”

According to the description in the specification (paragraph [0058]), “basic polygonal cross-section” includes cases where the opening of the bearing portion formed by wire electrical discharge machining, which is commonly used in the manufacture of dies, is hexagonal or dodecagonal. And according to the description in the specification (paragraphs [0054] to [0057]), since the shape of the “basic polygonal cross-section” becomes “generally polygonal shape” by changing said shape, the “basic polygonal cross-section” and the “generally polygonal shape” are essentially different concepts and must be distinguishable.

…

(2) The shape of the corner of the “generally polygonal shape”

The opening of the bearing portion of a die is formed by wire electrical discharge machining (Reference 31). In the machining of dies, it is usual to use an electric discharge wire of about 0.2 to 0.3 mm. Therefore, in actual machining, a circular arc with a radius of curvature of at least 0.2 to 0.3 mm is generated at the corner of the opening (References 31, 36, 37).

On the other hand, the specification does not indicate any criteria for determining the degree to which rounding the corners of the “basic polygonal cross- section” constitutes a “generally polygonal shape,” and the description in paragraph [0055] does not indicate what the parameters are when rounding the corners of the “basic polygonal cross-section” to make it a “generally polygonal shape,” nor does it indicate what the lower limit of the parameter is. (Furthermore, based on the description in paragraph [0055], the trial decision arbitrarily took out only the specific value of the radius of curvature “0.8mm” and read it as a constituent requirement of the present invention, thereby determining that the range of shapes included in “generally polygonal shape” would not become unclear. Such reading is an improper limitation interpretation because it clarifies an ambiguous description by interpretation, which should have been done by correcting the recitations of the claims.)

In addition, given that the technical significance of the present invention lies in the fact that the cross-sectional shape of the opening of the bearing portion of the die is “generally polygonal shape,” thereby eliminating angles where lubricant accumulates, it would be wrong to focus only on the value of the radius of curvature when determining whether the cross-sectional shape falls under “generally polygonal shape” or not, and it is necessary to look at the value of the radius of curvature relative to the length of one side. In the example described in paragraph [0055] of the specification, an arc with a radius of curvature of 0.8 mm is shown at the corner of the opening of the bearing portion with a square cross-section of 4 mm per side, which is similar to an arc with a radius of curvature of 0.3 mm at the corner of a square cross-section of 1.5 mm per side. (Also, when the cross-section of the opening is a 4 mm square, the corners of the opening are arcs with a radius of curvature of 0.5 mm, which is similar to when the cross-section of the opening is a 2.4 mm square, the corners of the opening are arcs with a radius of curvature of 0.3 mm). Thus, a person skilled in the art is unable to distinguish a shape in which the corners of the opening are arcs produced by ordinary processing by wire electrical discharge machining from a “generally polygonal shape” from their appearances, and is unable to determine what kind of shape belongs to a “generally polygonal shape,” and therefore, the “generally polygonal shape” recited in claim 1 is so unclear as to cause unforeseen disadvantage to third parties.

4. Defendant’s Counterargument

(1) Distinction between “basic polygonal cross-section” and “generally polygonal shape”

…

(2) The shape of the corner of the “generally polygonal shape”

- The purpose of this invention is “to provide a means of preventing the formation of lubricant clumps as much as possible and reducing the time required for the maintenance as much as possible, resulting in a reduction in the cost of manufacturing wires with polygonal cross-sections.” From the description of the specification, a person skilled in the art can easily recognize that “generally polygonal shape” means that the corners where lubricant accumulates are actively treated so that they are eliminated, and does not include the rounded corners that inevitably occur in wire electrical discharge machining. Furthermore, a person skilled in the art can easily understand that there is a difference between the “basic polygonal cross-section” and the “generally polygonal shape,” since active treatment to eliminate corners means to increase the radius of curvature compared to the roundness that inevitably occurs at the corners in wire electrical discharge machining.

- The plaintiff claims that if the cross-sectional shapes of the openings of the bearing portions of the dies are similar, there is no difference between them in terms of whether or not lubricant accumulates at the corners. However, whether or not lubricant accumulates at the corners of the opening depends solely on the size of the radius of curvature of the roundness of the corners. … Therefore, whether the cross-sectional size of the opening is 4 mm or 1.5 mm per side, active treatment to round the corners is less likely to cause lubricant accumulation than if the corners are left with roundness (roundness with a radius of curvature of 0.2 to 0.3 mm) that is inevitably caused by wire electrical discharge machining. There is no reason for the plaintiff’s above claim.

- The plaintiff claims that the trial decision arbitrarily took out only the specific value of the radius of curvature “0.8 mm” and read it as a constituent requirement of the present invention, thereby determining that the range of shapes included in “generally polygonal shape” would not become unclear. However, the trial decision did not take out only the specific numerical value and read it as a requirement for the present invention, but rather as an example in interpreting “generally polygonal shape,” and based on the description in paragraph [0055] of the specification, it merely explains the state in which the “basic polygonal cross-section” is actively treated so that there are no corners where lubricant can accumulate. There is no reason for plaintiff’s above claim.

5. Summary of Judgment

(1) Significance of “generally polygonal shape” of the present invention

According to the description of the claims and the specification, the “generally polygonal shape” of the present invention means that one or all corners of the “basic polygonal cross-section” are replaced with arcs, set of obtuse angles, or free curves in order to obtain the effect of the present invention (i.e., to prevent lubricant from accumulating at the corners of the opening of the bearing portion of the die) (hereinafter, replacing a corner with an arc, a set of obtuse angles, or a free curve is referred to as “rounding a corner,” and a arc, a set of obtuse angles, or a free curve formed at a corner is referred to as “roundness of the corner”). According to the description of the claims and the specification, the “basic polygonal cross-section” is understood to mean the cross-section of the opening in the conventional art (which is not actively treated to round the corners), and therefore, “generally polygonal shape” in the present invention means a polygonal shape in which one or all corners of the opening that has not been actively treated are actively treated to round them in order to obtain the above effect of the present invention.

(2) Distinction between “basic polygonal cross-section” and “generally polygonal shape”

As described in (1) above, “generally polygonal shape” in the present invention is understood to mean a shape in which one or all corners of the “basic polygonal cross-section” are rounded, and the “basic polygonal cross-section” and the “generally polygonal shape” should be clearly distinguished according to the meaning of them.

However, according to the evidence and the summary of the argument, it is recognized that the corners of an opening are inevitably rounded when a wire electrical discharge machining process is performed to form the opening. Then, the “basic polygonal cross-section” may also be a polygonal cross-section with rounded corners after a wire electrical discharge machining process, in which case it would be indistinguishable from the cross-section of the “generally polygonal shape” from their appearances, and thus the “generally polygonal shape” of the present invention is difficult to distinguish from the “basic polygonal cross-section,” and the technical scope of the present invention is not clear.

The smaller the diameter of the wire used for wire electrical discharge machining, the smaller the radius of curvature of the rounded corners.

→ There is no objective standard to determine how small the radius of curvature must be to be considered as an inevitable roundness and how large it must be to be considered as actively rounded.

(3) The shape of the corner of the “generally polygonal shape”

With regard to the roundness of the corners of the opening, there is no objective standard to determine how small the radius of curvature must be to be considered as an inevitable roundness and how large it must be to be considered as actively treated beyond an inevitably rounded roundness, and it cannot be said that it is objectively clear to what extent the radius of curvature must be to obtain the above effect of the present invention. Therefore, with respect to the “generally polygonal shape” of the present invention, even based on the description in the claims, the specification, and technical common sense at the time of the filing date of this application, it is not clear to what extent the corners of the “basic polygonal cross-section” must be rounded, and in this respect, the technical scope of the present invention is not clear.

Even if the radius of curvature of the rounded corners of the opening is smaller than 0.8 mm, the effect of the present invention (i.e., to prevent lubricant from accumulating at the corners of the opening) may be obtained.

The above value is for a square opening of 4 mm per side. If other polygonal shapes are included, it is not objectively clear to what extent the radius of curvature must be to obtain the effect of the present invention.

The ease of accumulation of lubricant at the corners of the opening can be affected not only by the size of the radius of curvature of the rounded corners but also by various other factors, and it is not recognized that a radius of curvature of 0.3 mm or less, for example, would uniformly prevent the effect from being obtained.

(4) Summary

As described above, according to the description of the claims and the specification, “generally polygonal shape” in the present invention means a shape in which one or all corners of the opening are actively treated to be rounded in order to obtain the above effect of the present invention. However, it is not possible to distinguish between the “generally polygonal shape” and the “basic polygonal cross-section” from their appearances, and it is not clear to what extent the corners of the “basic polygonal cross-section” must be rounded to correspond to the “generally polygonal shape” of the present invention. Therefore, the technical scope of the present invention is not clear, and the “generally polygonal shape” of the present invention must be evaluated as so unclear as to cause unforeseen disadvantage to third parties. There is also no evidence sufficient to recognize circumstances in which the “generally polygonal shape” of the present invention should be evaluated as clear.

6.Our Consideration

The use of terms “generally,” “about,” “approximately,” “substantially,” etc., in a claim is not immediately deemed unclear, but it is necessary to describe the specification and the drawings so that the scope of the matters specifying the invention with such terms is clear.

In this case, the definition of “generally polygonal shape” should have been defined in detail when the inventor consulted about this invention. The result might have been different if the fact that it is common knowledge in the art that wire electrical discharge machining is used to form openings, the fact that the corners of the opening are inevitably rounded, the radius of curvature of the inevitable roundness, and the difference from the radius of curvature of the rounded corners of the “generally polygonal shape” formed by active treatment could have been taken in account.

First, a numerical limitation on the radius of curvature would have been considered. Here in this case, the only example given was that the radius of curvature of the rounded corners of the opening should be about 0.8 mm when manufacturing a bar with a square cross-section of 4 mm per side, but we think this is not sufficient. If possible, it would have been necessary to provide a definition in the form of a formula, etc., that could be applied to any one-sided length and any cross-sectional shape. In addition to the radius of curvature, as mentioned above, there are many other parameters that can affect the solution of the problem of preventing lubricant clumping. Ideally, it would have been impeccable if these parameters could have been identified and formulas defined for them.

If there was recognition of the inevitable rounding of the corners when forming the opening, what about adding a recitation to the claim to require active treatment, such as “formed by active rounding process,” in order to differentiate the opening from the inevitable roundness (although product-by-process (PBP) claim issues may arise)? This may be a simple case, but a variety of arguments can be made and a lot of teaching can be obtained.